September 19, 2025 Curious why a 5-Axis Machine costs so much? Many shops focus only on the sticker price, but the real investment includes long-term value and efficiency. In this article, you'll learn why costs vary, common misconceptions about pricing.

Read More

September 17, 2025 Have you ever wondered how massive parts are machined with precision? A Bridge Mill is designed for exactly that need. It combines stability, extended travel, and efficiency, making it vital for modern manufacturers.

Read More

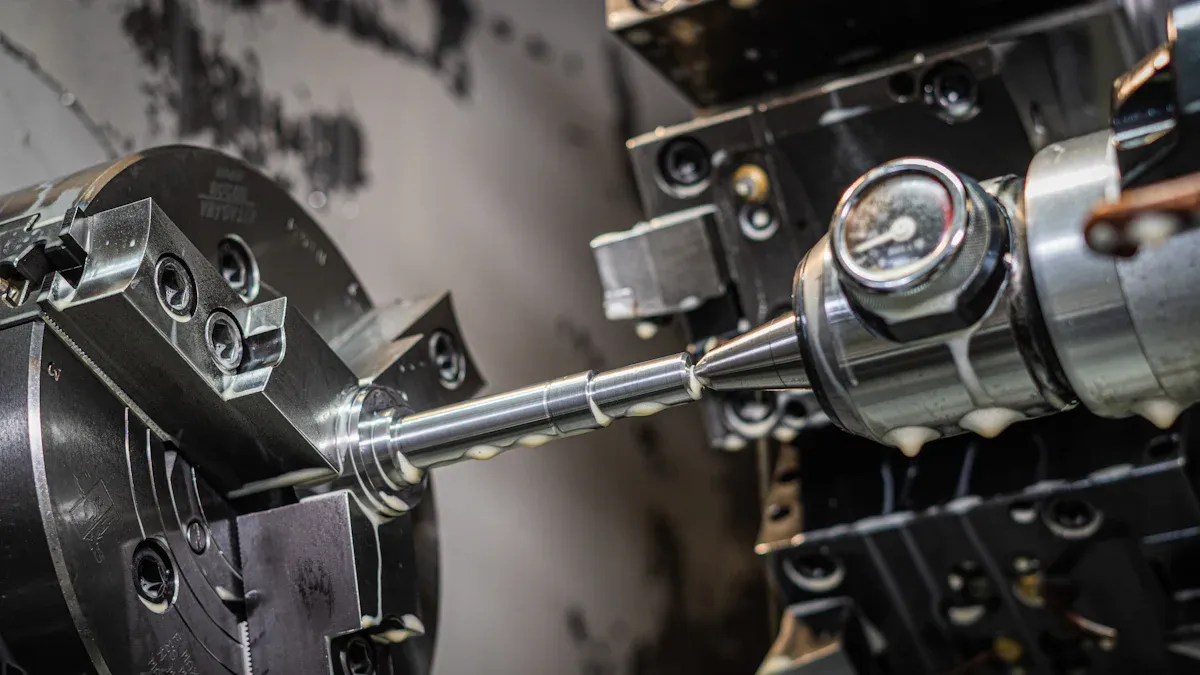

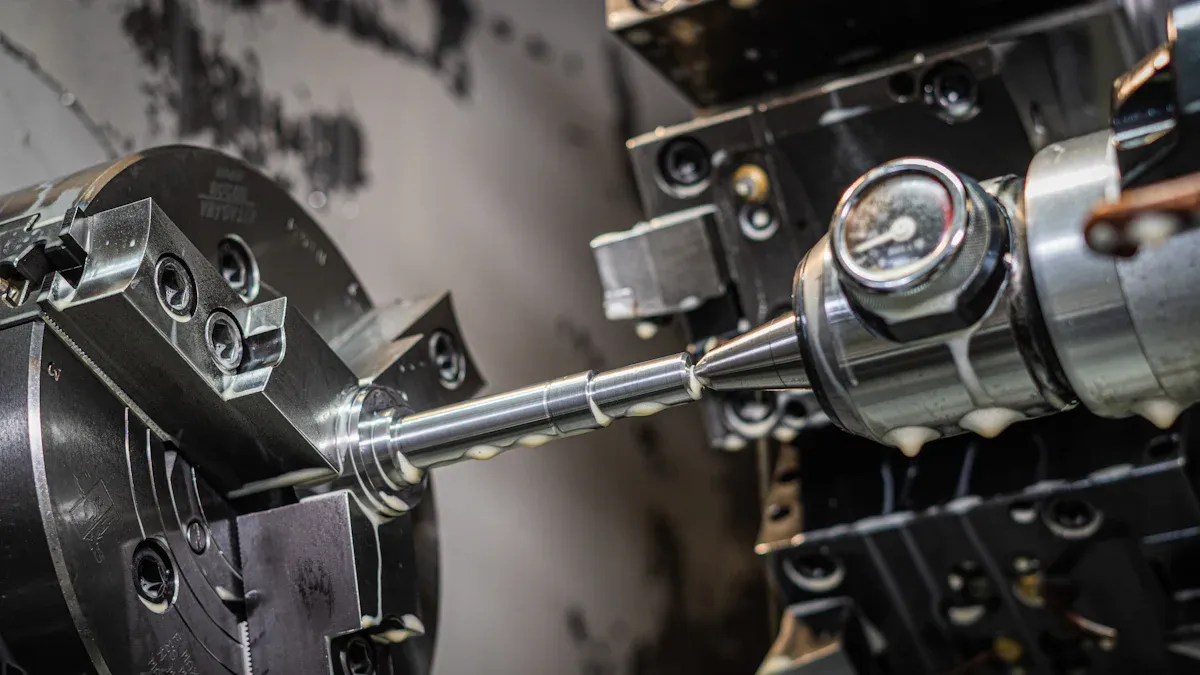

August 19, 2025 When you start using a lathe machine, you will notice several lathe chuck types. The most common are 3-jaw, 4-jaw, and 6-jaw chucks. Each type fits different needs in cnc lathe work. A lathe chuck holds your workpiece steady on the lathe machine. This makes sure your cnc projects stay accurate and safe. You need to know which chuck matches your part and job.

Read More

August 15, 2025 You can see a big difference between a cnc lathe and a cnc milling machine. In a cnc lathe, the workpiece spins but the cutting tool does not move. This makes it great for making shafts, screws, and round parts. A cnc milling machine holds the workpiece still and turns the tool. This lets you shape flat, slanted, or tricky surfaces.

Read More

August 12, 2025 Positioning accuracy in a cnc lathe shows the gap between where the tool should be and where it really is. Repeatability tells us if the machine can go back to the same spot every time. These two things are very important in cnc machining. They matter a lot in car and airplane making, where high quality and exact sizes are needed. The cnc lathe is popular in factories today because it gives steady results many times. Operators use these numbers to see if their cnc turning center can give the right quality and accuracy.

Read More