Provide the best processing solutions

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

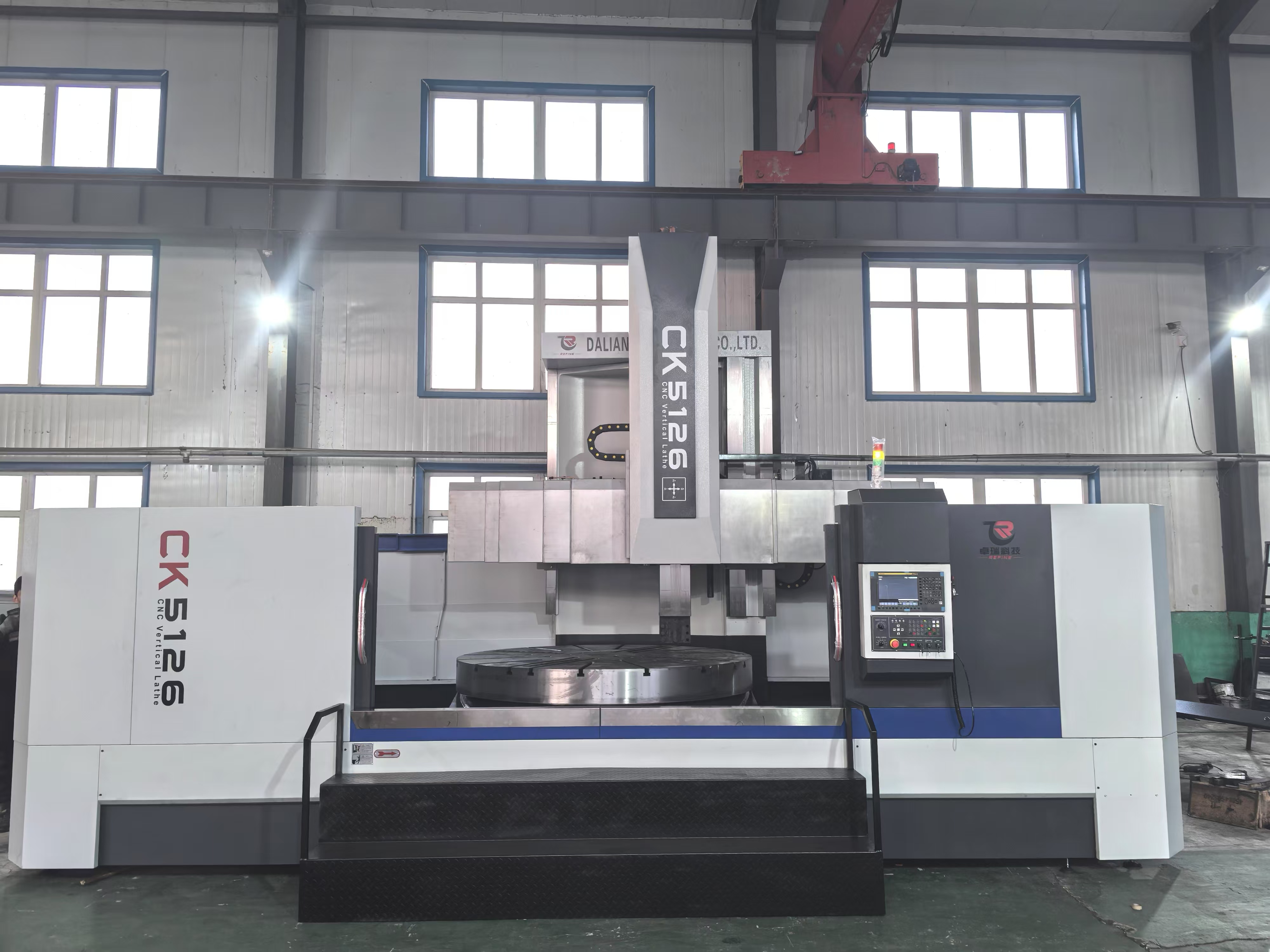

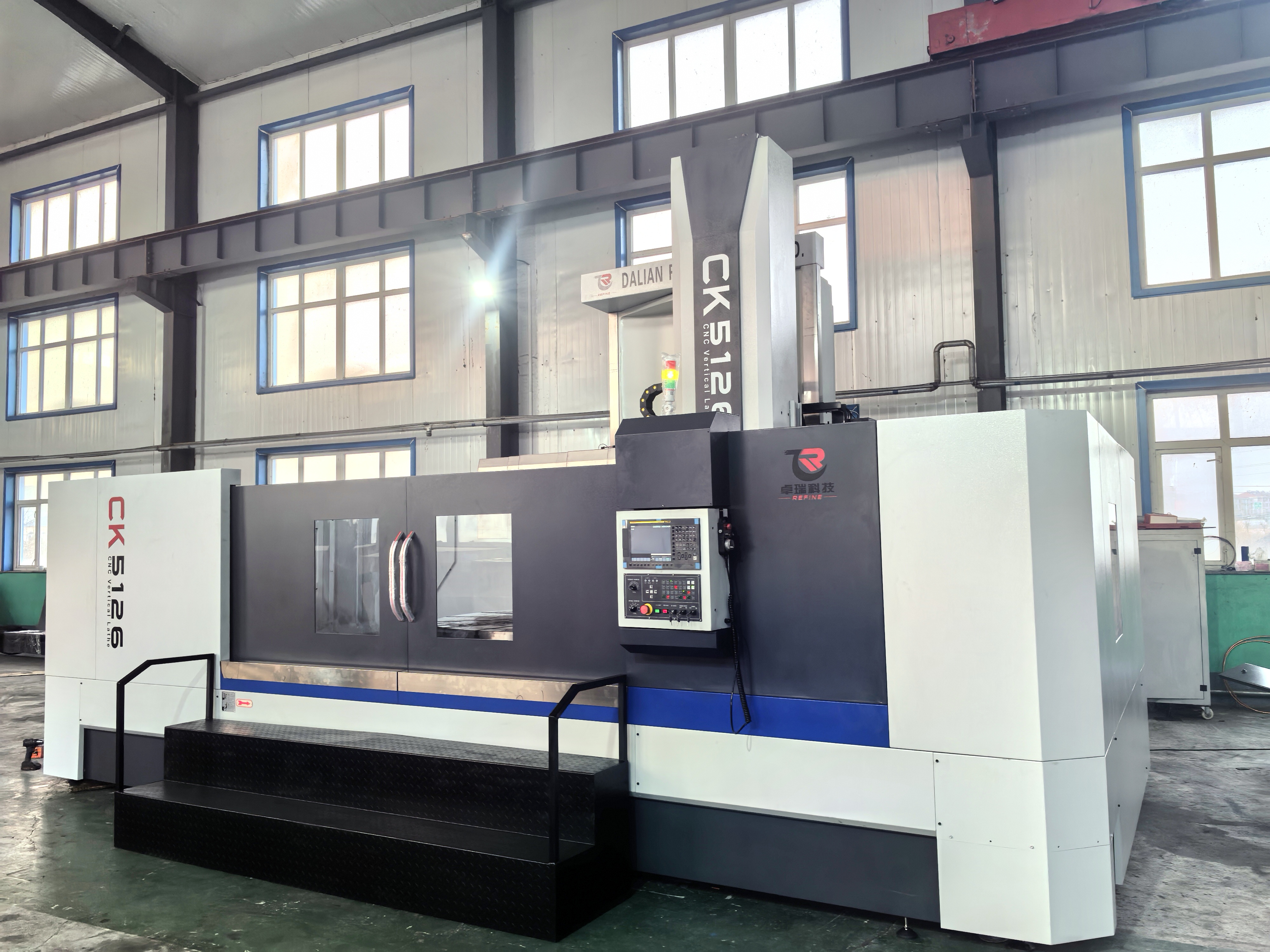

CK5126

Refine

DESCRIPTIONS OF CK5126

The machine tool is suitable for high-speed steel cutting tools, carbide cutting tools and various high-performance cutting tools, processing ferrous metal, non-ferrous metal and some non-metallic materials workpiece, in the machine tool can complete the internal and external cylindrical surface, internal and external cylindrical surface, plane, internal and external ring groove rough, fine turning process.

Product Parameters

Specification | Unit | CK5110 | CK5112 | CK5116 | CK5120 | CK5123 | CK5126 |

Max dia | mm | 1000 | 1250 | 1600 | 2000 | 2300 | 2600 |

Table dia | mm | 900 | 1000 | 1400 | 1800 | 2000 | 2300 |

Max workpiece height | mm | 800 | 1000 | 1000/1200 | 1200 | 1200 | 1350 |

Max workpiece weight | t | 2 | 3.5 | 5 | 8 | 8 | 10 |

Max torque of table | KN.m | 20 | 25 | 30 | 40 | 40 | 45 |

Table rotate speed range (4gear stepless) | r/min | 1-250 | 1-200 | 1-160 | 1-100 | 1-80 | 1-63 |

Max cutting force of the vertical holder | KN | 20 | 20 | 25 | 25 | 25 | 30 |

Tool rest feed range | mm/min | 0.1-500 | 0.1-500 | 0.1-500 | 0.1-500 | 0.1-500 | 0.1-500 |

Tool rest feed level(ungraded) | grade | stepless | stepless | stepless | stepless | stepless | stepless |

Horizontal travel of rail head | mm | 670 | 700 | 915 | 1050 | 1250 | 1450 |

Ram travel of rail head | mm | 650 | 650 | 800 | 800 | 800 | 800 |

Crossbeam travel | mm | 650 | 650 | 850 | 900 | 900 | 950 |

Fast moving speed of tool heads | mm/min | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

Beam lift speed | mm/min | 440 | 440 | 440 | 440 | 440 | 440 |

Q: What is the typical lead time for the CK5126?

A: Delivery takes 30-35 working days after order confirmation. Customization options such as additional tool stations or special workholding devices may extend lead time by 5-7 days.

Q: Can the machine integrate with third-party automation systems?

A: Yes, the CK5126 comes with standard M-code interfaces that support integration with robotic loading/unloading systems, barcode scanners for batch tracking, and IoT-enabled monitoring platforms for real-time production data analysis.

Q: What maintenance services are included?

A: We provide a 12-month warranty covering parts and labor. The package includes on-site installation, initial calibration, operator training, and lifetime technical support via phone, email, or remote desktop assistance.