October 17, 2025 3+2 vs. 5-Axis: What’s the Difference?5-Axis MachineIn modern machining, precision drives competition. But is 3+2 enough, or should you invest in a 5-Axis Machine? Aerospace, automotive, and medical sectors demand clarity. In this article, you’ll learn the key differences, pros, and when each method

Read More

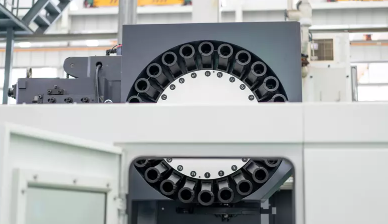

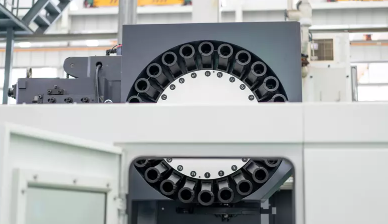

October 17, 2025 The term CNC lathe continues to be central in modern precision manufacturing and machining. Whether producing automotive shafts, medical components or electronics connectors, selecting the right type of CNC lathe is crucial.

Read More

October 16, 2025 In today's shops, myths around 5-Axis Machining still cause doubt. These misconceptions can block ROI and leave businesses at a disadvantage. In this article, we'll uncover common myths, explain why they persist, and show the real advantages.

Read More

October 14, 2025 Choosing the right motor can decide how efficient your CNC machine will be. Many people debate servo vs stepper motors, but the right choice depends on speed, torque, and accuracy needs.

Read More

October 14, 2025 In the world of precision machining, the CNC lathe stands as one of the most indispensable tools for producing accurate, repeatable, and complex parts.

Read More